Ever wondered how modern projects stay strong? PCE, or Polycarboxylate Ether, makes concrete flow better while enhancing durability. It also serves in cleaning and chemical processes. In this article, you will learn PCE’s applications and how it improves efficiency, safety, and sustainability across industries.

PCE applications in concrete significantly improve the mixture's flowability. By dispersing cement particles efficiently, PCE reduces the water-to-cement ratio while maintaining strength and durability. This allows for easier pouring, placement, and finishing of concrete structures. High-performance projects such as bridges, tunnels, and high-rise buildings particularly benefit from its superior workability.

In addition to enhancing fluidity, PCE minimizes cracking and shrinkage, contributing to long-term structural integrity. Its inclusion reduces the need for mechanical vibration, saving labor and energy costs on-site. Contractors find PCE indispensable for precast concrete and ready-mix applications, where consistent quality and performance are critical. Using PCE ensures the concrete achieves desired strength without compromising construction timelines.

There are several types of PCE superplasticizers, each tailored for specific applications. Standard PCE is suitable for most concrete projects, providing general water reduction and workability enhancement. Retarding PCE extends setting time, making it ideal for hot weather construction. Water-reducing PCE minimizes water content, enhancing durability. High-range PCE is designed for high-performance concrete, delivering maximum fluidity for demanding structures.

Selecting the appropriate PCE type depends on environmental conditions, project requirements, and desired concrete properties. Engineers should consider climate, project scale, and mix composition when choosing a superplasticizer. Proper selection ensures efficiency, cost-effectiveness, and structural performance. Using the wrong type may result in premature setting or inconsistent concrete quality.

Type of PCE | Key Feature | Best Use Case |

Standard PCE | General water reduction | Most concrete applications |

Retarding PCE | Extends setting time | Hot weather projects |

Water-reducing PCE | Minimizes water content | High-strength concrete |

High-range PCE | Maximum fluidity | Bridges, high-rises |

PCE for high-performance concrete is widely used in demanding construction projects. Bridges, skyscrapers, and infrastructure requiring long-lasting durability benefit from reduced cracking and improved compressive strength. By lowering water content without affecting workability, PCE enhances the concrete's density and longevity. Case studies show compressive strength improvements of up to 30% when PCE is correctly applied (data needs verification).

Self-compacting concrete also leverages PCE superplasticizers, allowing intricate molds and dense reinforcement without mechanical vibration. Infrastructure projects achieve higher safety standards and extended service life due to these improvements. PCE ensures uniform material performance across large-scale pours, reducing labor and maintenance requirements.

PCE offers several advantages over traditional superplasticizers. Its unique chemical structure promotes better particle dispersion, enhancing concrete flowability and reducing water demand. Compared to melamine or naphthalene-based superplasticizers, PCE improves long-term durability and decreases shrinkage. The environmental benefits include lower water consumption and reduced energy requirements for curing.

Additionally, PCE minimizes the need for mechanical compaction and labor, translating into cost savings. Its performance is consistent across different temperatures and climatic conditions, making it suitable for global construction applications. By integrating PCE, engineers can meet high-performance standards while optimizing material efficiency and sustainability.

PCE is a highly effective solvent in the dry-cleaning industry. Its non-flammable properties and ability to remove stains from natural and synthetic fabrics make it invaluable. PCE can be reused multiple times, reducing operational costs while maintaining cleaning efficiency. Its chemical stability ensures consistent performance over long-term use.

Dry cleaners combine PCE with detergents to enhance stain removal. Fabrics retain their texture and color, and delicate garments avoid damage. The long shelf life of PCE makes it a cost-effective and reliable cleaning agent for commercial operations. Regular monitoring and proper filtration further extend its usability.

Industries such as automotive, aerospace, and appliance manufacturing use PCE for metal degreasing. Its high boiling point allows for effective vapor cleaning, removing wax, oil, and other surface contaminants. Steam cleaning with PCE enhances metal surface quality while maintaining safety due to its non-flammable nature.

Vapor degreasing ensures uniform cleaning of small or complex metal parts, critical in high-precision industries. PCE’s efficiency reduces cleaning time and labor costs. Additionally, recycled PCE minimizes environmental impact, supporting sustainable industrial practices.

PCE serves as a versatile chemical solvent in manufacturing processes. It is used in paints, inks, rubber, and textile treatment, improving product quality and efficiency. Its stability and solvency make it suitable for various chemical reactions, ensuring consistent outcomes.

PCE helps reduce flammability in mixtures, enhancing workplace safety. Manufacturers benefit from improved process control and product consistency. Its role in specialty chemical formulations underlines its importance across multiple industrial sectors.

Proper handling of PCE is crucial to mitigate health and environmental risks. Protective equipment, adequate ventilation, and spill management protocols are necessary in all industrial applications. Regulatory guidelines set exposure limits to ensure worker safety.

Regular monitoring of air quality, proper storage, and employee training enhance workplace safety. PCE should be handled with care to prevent skin contact and inhalation of vapors. Awareness of its chemical properties allows for better emergency response planning.

PCE contributes to catalyst regeneration in petroleum refining. Its chemical stability and solvency help maintain catalyst efficiency and extend equipment lifespan. Used in isomerization and catalytic reforming, PCE enhances yield and operational efficiency.

Refineries benefit from lower downtime and improved reaction consistency. PCE also facilitates environmental compliance by reducing chemical waste. Its multifunctionality makes it a valuable addition to refinery operations.

PCE is critical in producing refrigerants and fluorinated chemicals. Its dielectric properties and stability allow safe handling and formulation. By replacing more harmful solvents, PCE provides an environmentally friendly alternative in chemical production.

Its low surface tension improves mixing and coating processes. Manufacturers achieve higher product performance with reduced environmental risk. This use emphasizes PCE's adaptability beyond construction applications.

In chemical manufacturing, PCE serves as a solvent for textiles, rubber coatings, and paper treatments. Its efficiency surpasses many traditional solvents, providing consistent extraction and coating performance. The result is higher product quality and operational efficiency.

Industries utilizing PCE in coatings report better adhesion and uniformity. Its compatibility with various polymers enhances its versatility. PCE is a reliable choice where precise chemical performance is required.

Exposure to PCE can cause skin, eye, and respiratory irritation. Prolonged or high-level exposure may lead to liver, kidney, or neurological issues. Understanding these risks is essential for workplace safety planning. Workers must be trained in safe handling and emergency response.

PPE, ventilation systems, and chemical spill protocols are critical. Neutralization methods and proper storage further minimize risk. Educating staff reduces incidents and ensures compliance with safety regulations. Routine monitoring of air and surfaces ensures ongoing protection.

PCE can persist in air, soil, and water, making environmental management essential. Regulatory measures focus on containment, recycling, and safe disposal. Sustainable practices include reducing emissions and proper wastewater treatment. Adopting these measures protects ecosystems and maintains compliance.

Determining the correct PCE dosage is crucial for both concrete and industrial applications. Overdosing can lead to segregation, reduced strength, or delayed setting, while underdosing may compromise workability and performance. Professionals recommend testing small pilot batches before full-scale implementation to fine-tune the dosage. Accurate mixing ensures uniform dispersion, consistent material quality, and reliable performance in high-performance or self-compacting concrete projects, ultimately enhancing structural durability and efficiency.

Maximizing the benefits of PCE requires a careful balance between operational efficiency and worker safety. Automated dosing and mixing systems can ensure consistent performance while minimizing human exposure. Following safety protocols, including proper ventilation and PPE, prevents health hazards without reducing productivity. Efficiency and safety are complementary; projects that integrate PCE correctly achieve better flowability, improved concrete strength, and safer industrial processes simultaneously. Strategic planning allows teams to optimize resource use while mitigating risks associated with chemical handling.

PCE provides both environmental and economic advantages in large-scale projects. By reducing the water-to-cement ratio, PCE lowers water consumption and energy requirements for curing. This reduction in resource use translates into measurable cost savings and contributes to sustainability objectives. In addition, the improved durability and long-term performance of PCE-enhanced concrete reduce maintenance needs, minimizing operational expenses. Incorporating PCE not only improves material efficiency but also supports eco-friendly construction practices, making it a valuable tool for sustainable and cost-effective project management.

PCE offers superior performance compared to traditional solvents used in cleaning and industrial manufacturing. It combines efficiency, safety, and environmental benefits, making it an increasingly preferred choice across industries. Its high solvency ensures faster, cleaner processing while reducing flammability and exposure risks. Companies adopting PCE gain operational advantages such as consistent results, compliance with environmental regulations, and reduced chemical waste, enhancing both productivity and sustainability.

Compared to conventional superplasticizers, PCE significantly improves workability, compressive strength, and long-term durability of concrete. Its unique molecular structure ensures uniform cement particle dispersion, reducing shrinkage and cracking. Projects benefit from extended service life, lower maintenance costs, and consistent quality even under challenging environmental or load conditions. By enabling high-performance concrete applications, PCE allows engineers to meet demanding design specifications while improving construction efficiency and material reliability.

PCE’s versatility makes it suitable for construction, chemical manufacturing, and industrial cleaning applications. It performs reliably across varying climates, temperatures, and project scales, from large infrastructure projects to specialty chemical formulations. Companies leveraging PCE can standardize processes, simplify procurement, and reduce training complexity for staff. Its multifunctionality enables seamless integration into existing workflows, delivering consistent results, improved operational efficiency, and environmental compliance across diverse industries.

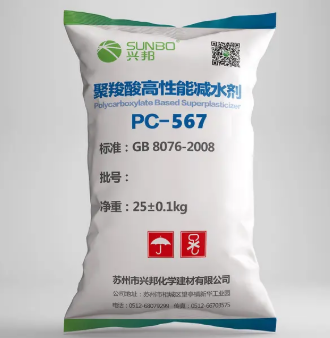

PCE improves concrete and industrial processes efficiently. It enhances durability, workability, and safety. Suzhou Sunbo Chemical Building Materials Co., Ltd. offers high-quality PCE products that deliver consistent performance and environmental benefits. Their solutions support sustainable, cost-effective, and high-performance applications across industries.

A: PCE, or Polycarboxylate Ether, is a superplasticizer that improves concrete workability, durability, and performance. PCE applications in concrete help reduce water usage and enhance long-term structural strength.

A: PCE for high-performance concrete lowers water content while maintaining flowability. It allows easier placement in demanding projects like bridges and skyscrapers, ensuring stronger, long-lasting structures.

A: PCE in the construction industry enhances workability, reduces cracking, and increases compressive strength. It also supports environmental goals by lowering water and energy usage.

A: Yes, Polycarboxylate ether superplasticizer uses extend to industrial cleaning, chemical manufacturing, and metal degreasing, offering efficiency, safety, and cost benefits across sectors.

A: Selection depends on project type, environmental conditions, and concrete requirements. PCE applications in concrete require proper dosage and mixing to optimize performance and durability.

A: PCE provides better particle dispersion, superior flowability, reduced water demand, and long-term durability. It outperforms melamine or naphthalene-based alternatives in high-performance concrete.

A: Proper handling includes PPE, ventilation, and correct storage. PCE applications in concrete and industrial processes must follow safety protocols to reduce health and environmental risks.

A: Yes, PCE can lower costs by reducing water and energy use, minimizing labor for vibration, and extending concrete lifespan. Efficient PCE for high-performance concrete ensures cost-effective outcomes.

A: PCE reduces water consumption and energy use, enhancing environmental sustainability. Its use in PCE applications in concrete supports green building initiatives and regulatory compliance.